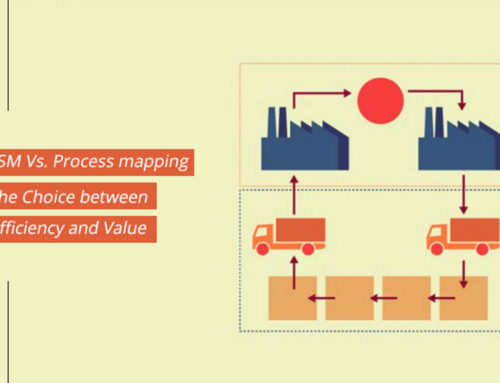

Conveyors are used for transporting materials and products around the factory. They are installed almost all around the food factory to move loads of all shapes, sizes, and weights with ease. If it were human to do this job, then it would be very arduous and costly.

To achieve the highest productivity and profitability in food processing, conveyors play a vital role. These machines reduce labor input and cost. They increase product output. Some tips to consider for conveyors in the factory before buying or improving their functionality are discussed below.

To achieve the highest productivity and profitability in food processing, conveyors play a vital role. These machines reduce labor input and cost. They increase product output. Some tips to consider for conveyors in the factory before buying or improving their functionality are discussed below.

Critical considerations for conveyors in a world-class food factory:

1) Design and Material

It is a known fact that food production’s main priority is to provide a product with complete safety protocols and make sure no contamination breaks out. So for that

- The usage of stainless steel (SS-316) to make food conveyors is recommended. This material can endure high power washdowns, and they don’t have any niche or crevices that might nurture any bacterial growth.

- Customization of the conveyor’s design according to the needs and requirements of the production is also recommended.

- Due to sanitizing concerns, the conveyor’s washdowns should include belt lifters, spray bars, and motors that can be enclosed. Such conveyors will be easy to clean and washdown according to sanitary guidelines.

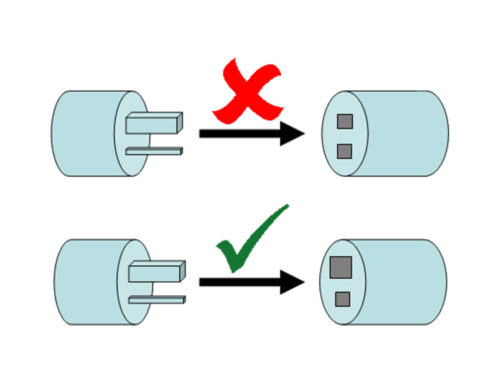

2) Power and Air Supply

Another point to keep in mind while choosing a conveyor is comprehending that what kind and limit of power and air supply your factory building has. The voltage limit should also be acknowledged. Conveyors usually require the power of 120 in single-phase, 220 in single-phase, 230 in three-phase, and 480 in three-phase.

3) Resilience and Capacity

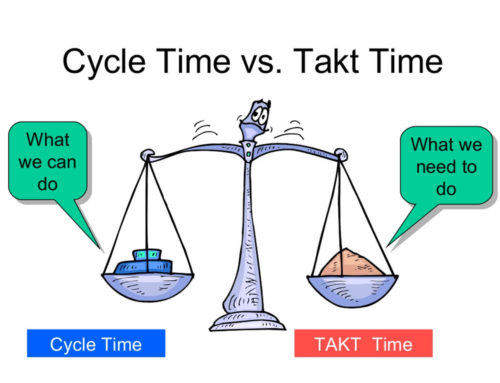

Conveyors are crucial in every food-producing factory, and they need to be very strong to work efficiently. For that purpose;

- Make sure the capacity and capability of the conveyor are according to your essential product requirement.

- Conveyors must be able to withstand the required weight of the food product. If not, then this will slow down the operational process, and the machine system will need to work harder with force, and overall effective production will decline.

- Additionally, these machines should be able to run various shifts.

- They also need to be vigorously cleaned with chemicals, so they must have the ability to hold up all this process.

This way, the production rate will boost, and the operational efficiency will be higher only when the machine damage occurrences are rare.

4) Maintenance

While getting a conveyor, remember that overall productivity will be higher when the conveyor shuts down for an insignificant amount of time. For this;

- The conveyor should be low maintenance.

- The preferred conveyor must not need regular repair and maintenance since a conveyor that is turned off is not producing any revenue for the factory business. So, it is better to choose a conveyor which needs less maintenance and less amount of time to remain shut off.

- Also, assure that it is accessible and provides access to the area where most work is required to be done.

5) Belting

The belting of the conveyors varies on the kind of food that is being produced. So it must be selected wisely and according to the requirements.

- Mesh belting is used for wet or slippery food

- The solid belt is best to be used for dry and solid food product

- Activated roller belts are often used to automatically merge the product and sort or arrange the food products.

6) Employee Safety Obligations

One of the main priorities and concerns should be the safety of factory workers. Conveyors should be designed and bought with proper safety features, so no risk of harm or injury will be upon the employees. Perceive and understand where on the conveyor line, the workers will be standing and what work they will be performing. Some safety features to be considered while buying conveyors are

- Proper ergonomic stands

- Appropriate safety guards

- Shut On and Off switches

Conclusion

Before contacting or dealing with any supplier, food factory officials must measure and note all the dimensions or requirements of the products that need to be conveyed. It may include the density of the material and weight of the packages that hold an impact on the conveyor.

Accurate determination and understanding of the overall weight and density of the product will aid in getting the best conveyor. Also, the tips, as mentioned earlier, must be considered for effective conveying processes. So, food factories will be able to gain much profit from your production plant, and the overall result will be exceptional.